The history of Goodyear welt

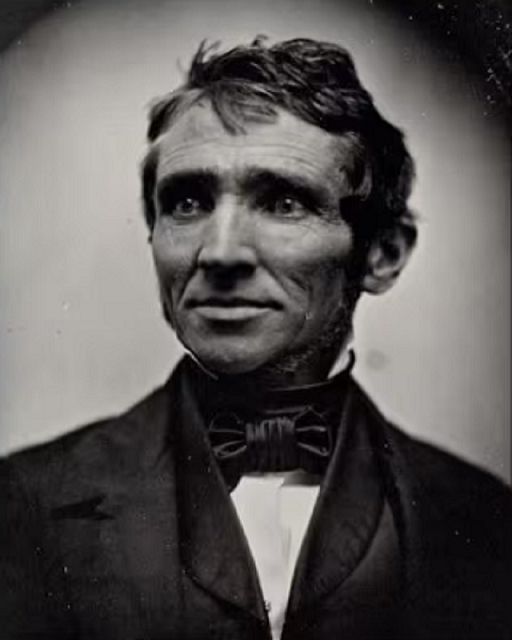

Before the Industrial revolution, shoemaking craftsmen needed to use awls to taper holes and then sew the welts by hand, which is the hand welt process. In 1871, after the start of the second industrial revolution, a patent called "Goodyear Shoemaking Technology" was approved by the United States Patent Office. A brand-new sewing machine was invented that could replace manual work to remove soles and sew inner threads. The inventor was Charles Goodyear. Mr. Goodyear was an American inventor, known as the "Father of Rubber" for his invention of vulcanized rubber.

Charles Goodyear and Goodyear shoe machine

The process of the Goodyear welt

The process of the Goodyear welt is as follows: Firstly, paste a layer of canvas strips on the insole, so as to form a rib structure similar to manual slotting. And then use a machine to complete the sewing of the welt,upper and insole. It is worth noting that the Goodyear shoe machine only sews inner threads and has nothing to do with outer threads. As early as 1856, Lyman Reed Blake had invented the Rapid stitch machine, a machine that could sew outer stitches (Lyman Reed Blake was also the inventor of the Blake process). The emergence of the Goodyear shoe machine has greatly improved the production efficiency of shoes. Together with the upper sewing machine and the rapid stitch outer thread sewing machine, the shoemaking industry has been brought into the machine age, liberating manpower.

Now, we can draw a clear conclusion that the Goodyear welt is used to replace Hand welt, and it has been tied to the machine since its birth. Shoes with welts sewn by craftsmen can only be called “hand welt” , not Goodyear welt.

We- China Xinxing Guangzhou Imp&Exp Co., Ltd. can help you customize what you want.